Walmart Testing Grocery Picking Robot in Salem Store

Over the past few years, Walmart has been incorporating robots and artificial intelligence into their stores and warehouses. Whether it be using AI to scan shelves, clean floors, or make deliveries, the company is embracing technology in order to keep up with competitors like Amazon and Target.

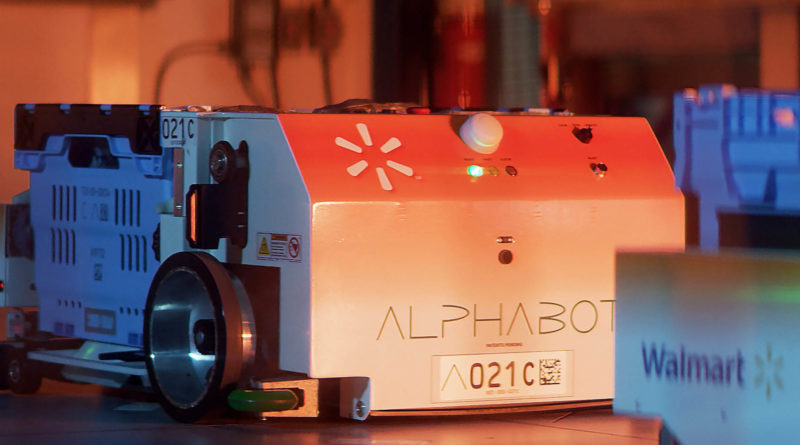

At their 20,000 square-foot facility in Salem, New Hampshire, the company is testing a new grocery picking robot. It’s called the Alphabot and it comes from startup Alert Innovation.

The system uses autonomous carts to retrieve items ordered for the online grocery service. After it retrieves the items from the warehouse shelves, Alphabot delivers the products to a workstation, where a Walmart associate checks, bags and delivers the final order.

Autonomous Carts Move Horizontally and Vertically

The bots operate on three axes of motion which makes a more flexible system than is typically found in traditional fulfillment centers and warehouses. The carts can also move both horizontally and vertically without any lifts or conveyors making them adaptable to all types of spaces.

When customers pick up their orders, workers can retrieve the items from one of several stations attached to the Alphabot shelving system. Workers simply input a grocery order number and out pops the bins belonging to that order. Inside the bins are the groceries, all bagged and ready to go.

“By assembling and delivering orders to associates, Alphabot is streamlining the order process, allowing associates to do their jobs with greater speed and efficiency,” said Brian Roth, Senior Manager of pickup automation and digital operations. “Ultimately, this will lower dispense times, increase accuracy and improve the entirety of online grocery. And it will help free associates to focus on service and selling, while the technology handles the more mundane, repeatable tasks.”

Grocery Picking Robot Learns Over Time

The Alphabot also shares data in real-time and as it learns the stocking will get “smarter” over time. This will lead to a more seamless grocery pickup and delivery experience, making substitutions easier to anticipate and fill.

Automated grocery systems are estimated to pick and pack orders as much as 10 times faster than a human worker. This could help companies expand their online grocery service as demand grows.

“We never want to be in a position to tell an online grocery customer they can’t have an item,” Roth said. “We’ll be able to look at datasets and fairly say ‘these two brands of pasta are typically bought together,’ or ‘here’s an item a consumer buys often,’ and use that information to make more informed substitutions.”

The pilot program has been operating at Walmart’s Salem location since mid-2019. The company is still studying and refining the grocery picking robot. It has plans to roll out Alphabot to more locations in the near future.

Other sources: Business Insider

Check out our articles on a Korean snow removal robot and AI that can look at a pizza and give you the recipe.